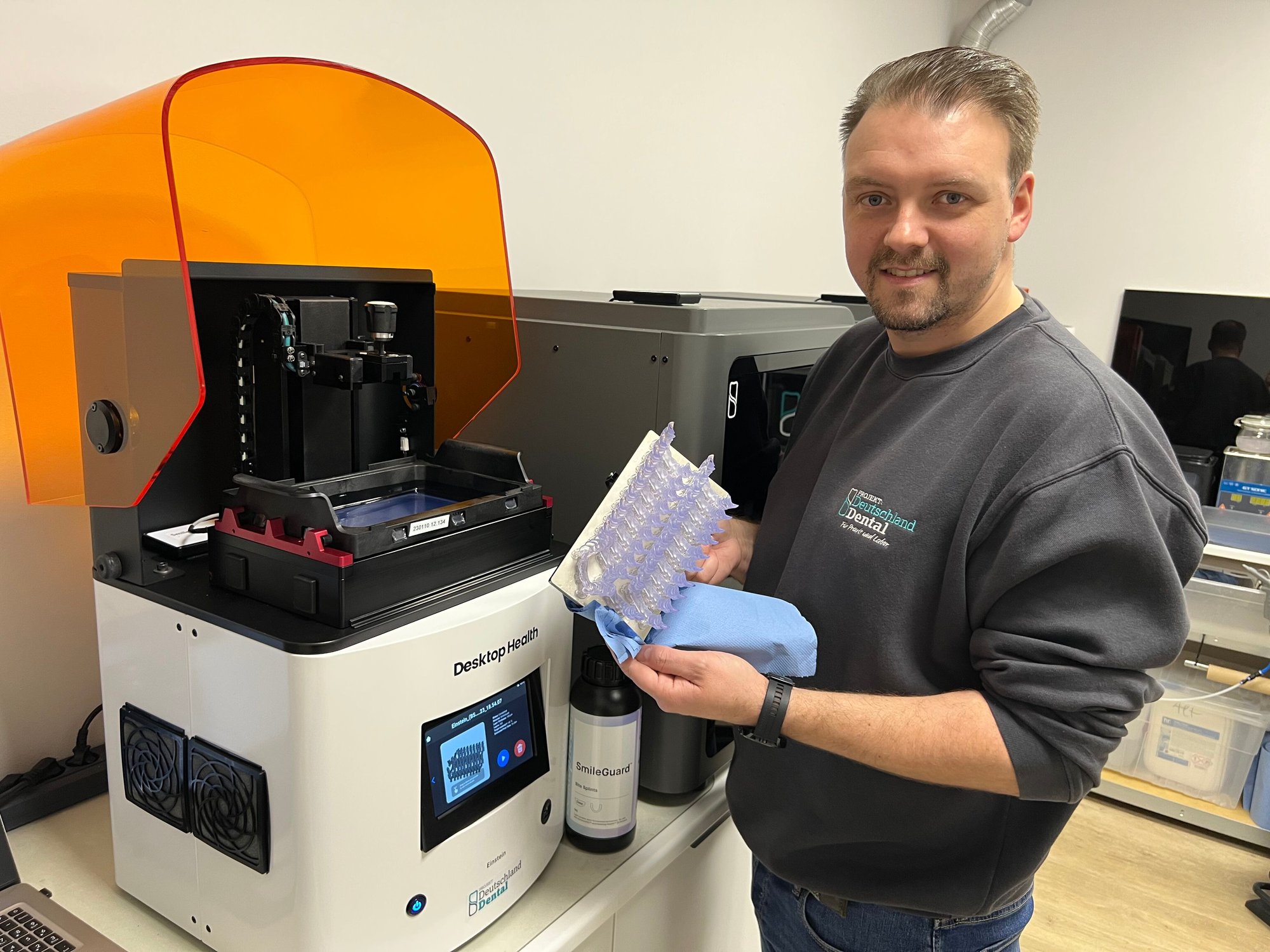

How a German Dental Lab Delivers High-Quality Dental Splints and Models to Increase Productivity

Projekt: Deutschland Dental (PDD) revealed how they consistently deliver the highest quality dental models for its customers in record time while extremely saving production costs & time and growing their business.

The success in a glance:

- Significant reduction of production costs compared to traditional manufacturing

- Extreme time savings in model production

- Increased productivity despite skilled labor shortage

- Highly precise, strong, and clear dental models

- Zero-waste bite splint fabrication

Get your exclusive case study

“Now, as soon as we’ve got the patient scan from

the dentists, we can manufacture the models right away

on the same day. The costs, and especially the times

we can save in the productions, are extreme."

Kai Weiffen, CEO of Projekt: Deutschland Dental

.jpg)